The largest plant in Turkmenistan for the production of high-quality fresh water is located in the Ak Bugday etrap of Ahal velayat.

The plant was built in 2010 by the Turkish company Polimex, its capacity is 250 thousand cubic meters of drinking water per day.

Next to it there are two water plants built earlier; including the very first structure with a capacity of 100 thousand cubic meters per day, which was built in 1969 and is still operating today, reports the publication “Turkmenistan: Golden Age”.

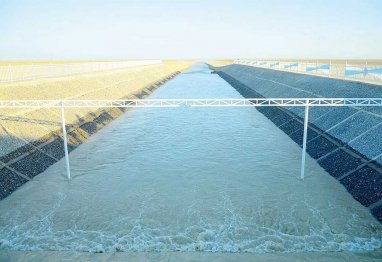

Water intake to supply the country's cities is carried out from the Karakum River.Work on the production of clean water begins with settling it in an open reservoir, where it enters through a dense wide layer of reeds, which, as is known, is an excellent bioplate for purifying water from organic and other impurities.

Nearby is a powerful pumping station, from where water is supplied to the factory workshops without interruption.

Through two settling tanks, water is supplied to the aerator to enrich it with oxygen and get rid of the specific odor.Then, through a complex system of interconnected deep settling tanks, the water is treated first with a coagulant, which attracts and precipitates suspended particles, and then with a suspension of flocculant, which is used in the treatment of industrial and waste water.

After chlorination, the water is supplied to the workshop where the chemicals are removed through the use of a dissolved salt coagulant and liming, which binds and precipitates a number of particles. This achieves decarbonization of water, reducing alkalinity and temporary hardness.

The water is purified repeatedly; finally - in twelve vast pools. After the procedure of getting rid of pathogenic microflora, this water can be drunk.

There is a laboratory at the plant where samples from all stages and at the finish are checked hourly, the quality and chemical composition of the water is determined.

The plant operates around the clock, which is provided by 180 specialists, of which 30% are women.

The capital's water use is complemented by a modern complex of underground canals and collectors for transporting drainage, stormwater and sewerage out of the city, which is an important stage for the development of urban infrastructure and ensuring environmental protection. These waters enter underground tunnels and are transported by gravity to the sewage treatment plant (KOS-300).

The facility periodically checks the condition of the ponds and the chemical composition of the water they contain in the process of preparing them for reuse.An analysis is made of the quality of incoming contaminated wastewater and the level of their purification, comparing the results with the stipulated acceptable parameters of physical and chemical indicators in accordance with the sanitary standards of Turkmenistan.

All processes at KOS-300 are controlled from the control center in the service building. Disinfection of treatment water is carried out according to a long-established scheme.

After inspection by the sanitary and epidemiological service, this water becomes suitable exclusively for irrigating forest plantations, fodder or industrial crops.